By Dave Dunbar

National Sales Manager

Successful manufacturing companies always have ways to differentiate themselves from their competitors. The last thing that an established brand wants to deal with is selling a product that is functionally identical to other available options in the marketplace and being forced to engage in price wars that descend into a never-ending race to the bottom. When a brand is unique, the customer can’t make an apples-to-apples comparison and pricing considerations move to the back burner. As it turns out, General Pipe Cleaners has several unique products and drain cleaning equipment with features that set us apart from the competition. Here are six examples.

We like to make the point that the cable, or snake, is the most important part of a drain cleaning machine. It is the cable that goes down the drain and physically dislodges the obstruction or blockage. The machine itself, no matter how sophisticated or innovative, is simply a delivery system for the cable. You could have a stainless steel drain cleaning snake, a machine that is computer operated, and solar powered, but if it was delivering inferior cable down the drain, the operator would not be successful. Because of this fact, it is crucial to have the best cable available.

Flexicore cable is unique in the industry. We start with a 49-strand aircraft quality wire rope, and then tightly coil spring steel around it. The reason that we do this is to change the way the cable reacts to torque when in use. When our machines are rotating in the forward direction and they encounter resistance down the drain, torque is produced. This torque causes the outer spring of the Flexicore cable to contract. However, because the wire rope is already in the way, it has nowhere to go.

The cable reacts mechanically to this situation by stiffening and strengthening when under torque, exactly when the end user needs it the most. Due to the nature of our manufacturing process, Flexicore cable can transfer more torque from the motor to the cutting head than competitive brands. Because of this, they are safer, can do more work, and are less likely to kink or break than competitive cables.

Plumbers like to say that the Kinetic Water Ram is the best kept secret in the industry! When our sales reps are demonstrating this product at trade shows and counter days, often a plumber will walk by and say “do you know what I hate about this machine? It’s too fast!”

The problem for them is that if the right conditions exist to use the Kinetic Water Ram, it might only take the plumber 30 seconds to open a completely clogged drain, sometimes creating an embarrassing situation since they usually charge by the hour! If the worst thing that you can say about a product is that it’s too fast, then it must be worth having!

So, what are the ‘right conditions’ that allow the Kinetic Ram to be so successful? The secret is that there must be a solid column of water between the clog and the drain opening, because the Kinetic Ram simply sends a shock wave down the pipe that either strikes the obstruction and disintegrates it or knocks it into a bigger pipe. Just pump it up, make sure that you have a good seal over the drain opening, and then pull the trigger. It’s that quick!

The Kinetic Ram creates a powerful shock wave that follows the contours of the pipe, with 98% of its energy against the obstruction. Only 2% is lost against the walls of the pipe. This tool is a must-have for facility maintenance engineers as well as service plumbers.

General’s unique ClogChopper cutters can do it all! Their round shape allows them to act like starting tools, negotiating the pipe’s twists, turns, and tees with ease. When our drain auger reaches the obstruction, they quickly bore through whatever is blocking the line. The ClogChopper’s hardened steel construction with self-sharpening blades gives it durability and performance under the toughest of conditions.

The feedback that we’ve been getting from our customers is that the ClogChopper quickly becomes their go-to cutter choice because it can handle so many of the challenges that occur when cleaning a drain. If fact, we’ve heard of several rental stores that weld or Loctite the cutter on the end of the cable before the drain cleaning machine leaves the store. It’s the only cutter you need!

Super Vee® Slide-Action Grip Shield

When General introduced the Slide-Action Grip Shield for the Super-Vee handheld electric drain cleaning machine almost fifty years ago, we knew that it would be a game changer. However, we didn’t know that this unique design would enable the Super-Vee to become the largest selling electric drain cleaner in history! Essentially, this feature creates an easy-to-use slide-action chuck that grips the drain cleaning cable when you pull back on the grip shield and releases when you slide it forward.

So, instead of stopping to twist a chuck, you’re simply slide the grip shield back and forth, which most users find to be much faster and easier to use. Plus, once you have more than five or six feet of cable in the drain, there is more friction in the pipe than in the drum. This allows the user to combine a gentle back and forth rhythm for even greater speed and convenience. Our customers tell us is that it’s hard to go back to other types of handheld machines once you get familiar with the Super-Vee!

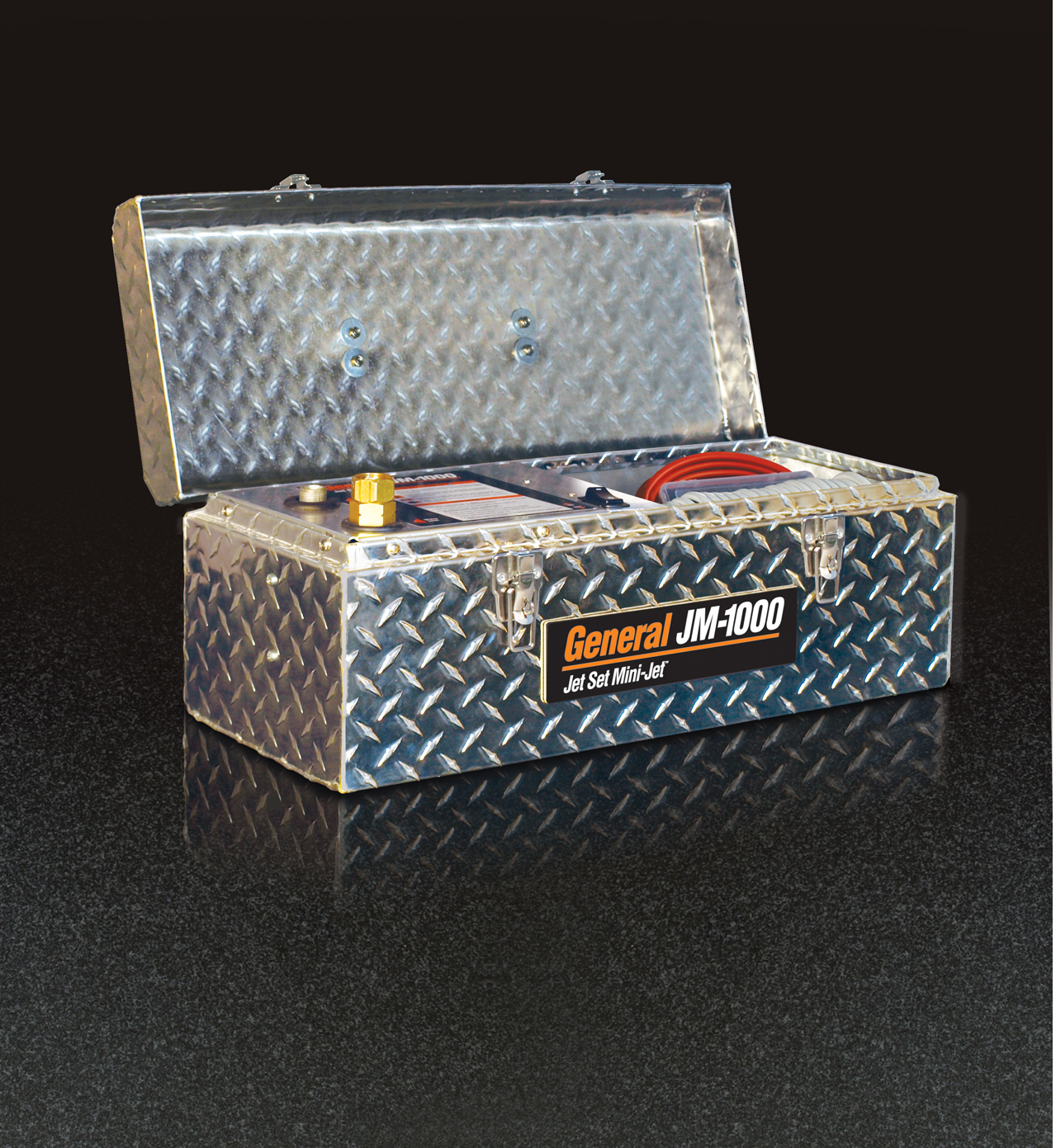

Jet-Set Vibra-Pulse®

When plumbers and drain cleaners began using high pressure water jetters to clean clogged pipes, they found that these devices did a much better job removing grease, sludge, sand, and ice than snake-style machines. For this reason, water jetters quickly became the go-to machine for soft stoppages. On the other hand, contractors found that the high-pressure water hoses that they inserted into the pipes could get stuck in the line. High pressure hoses are usually made of rubber or plastic, and as such they develop a lot more friction against the walls of the pipe than do metal snakes or cables.

Because of this, it’s easier for hoses to become stuck in the drain, particularly with lower powered electric jets, creating a dilemma for the contractor. We often say that when you get a hose stuck in a drain, it’s the beginning of a bad day, because there is no easy way to extricate it without digging up the pipe. The likelihood of jetter hoses getting stuck in the drain is the reason that every major manufacturer of high-pressure water drain cleaning devices have designed ways to vibrate the hose while in use. Vibration breaks the surface friction between the hose and the pipe and makes it much less likely for a problem to occur.

What sets General’s Jet-Set apart from the competition is that we don’t starve the high-pressure cylinders of water on most of our units when the Vibra-Pulse is engaged. Because of this, our pumps are much less likely to build up excess heat while in use, which increases reliability and durability.

Several features set the Flexi-Rooter 100 flexible shaft drain cleaner apart from its competitors. First, it has a stiffer flexible shaft and sheath, which lets the operator power through stubbornly clogged drains. Since their inception, flexible shaft units have had the reputation for being unable to clear a severely clogged pipe. They do a great job of cleaning up after a drain has been opened, as well as milling, pipe replacement prep, and de-scaling. However, until the roll out of the Flexi-Rooter 100, this type of machine lacked the ability to deliver the forward momentum necessary to unclog the toughest drains. General has delivered a game changer with this innovative drain cleaning tool because the contractor can now ‘do it all’ with one machine. Interestingly, the more familiar a customer is with other brands of flexible shaft machines, the more positive feedback they give us about their experience with the Flexi-Rooter 100!

All of these examples of unique products and features illustrate General’s motto; the toughest tools down the line! We go the extra mile in research, design, and manufacturing to ensure that our tools can do the job when you need them. Whether you require a large sewer machine for sewer lines or a drain auger for a clogged toilet, a compact drain machine for a clogged sink, or a multipurpose machine that can deal with a wide range of situations, we have what you need, and the warranty to protect them.

If you have any questions about any of these products or features, please feel free to call the Drain Brains at 800-245-6200, or visit our website at www.drainbrain.com