In this series on How to NOT Break Your Stuff, we’ve talked about how your attitude towards the job, as well as the quality and type of equipment that you use, can affect the longevity of your tools.

Contractors who are patient and careful on the job and who practice preventative maintenance after the job tend to break their stuff less often. And, investing in more durable equipment pays off in longevity. Now, let’s talk about decisions and work habits that prolong the life of your water jetter hose.

Check Your Surroundings

Most water or sewer jetter hoses do not have a braided metal exterior, but rather a plastic or rubber plastic composite coating. Although this gives them the flexibility to do their job, it makes them susceptible to cuts and abrasion. Make sure to keep them away from sharp edges, even before they go down the drain! We have seen many hoses returned to our factory that were cut coming around the corner several feet away from the cleanout or drain. Be aware of your surroundings. Also, be very careful not to scrape the hose as you feed it down the pipe. The rough edges on cast iron pipes can be very unforgiving to jetter hoses. We sell a small plastic adjustable sleeve designed to fit into the drain and smooth the way for both water jetter hose and camera system pushrods. We recommend using something like this whenever the entry point of the pipe has a rough edge and could possibly cut or make an abrasion.

Make Sure Your Hose has a Vibration Feature

Vibration is another issue when it comes to preserving the life of your jetter hose. It’s crucial that you have the ability to vibrate your hose as it’s going through small lines or tight spots. When the industry first started using high-pressure water cleaners in the 1980s, they simply took a pressure washer, a length of smooth hose and a backward facing nozzle and put it down the drain. Immediately, people realized that they were getting their hoses stuck in the pipe a high percentage of the time. Unlike a steel cable that can be pulled out of a pipe with enough force, a stuck hose is always the beginning of a bad day!

What was happening was that the rubber/plastic composite that makes up the outside of the jetter hose has considerably more surface friction than a steel cable. The solution was to devise a way to vibrate the hose while in use. This vibration breaks up that surface friction between the hose and the sides of the pipe and allows you access and exit from tight spots. Literally every major manufacturer of drain cleaning equipment has a way to vibrate their jetter hoses to prevent entrapment. Learn how your version of Vibra-pulse works and use it when appropriate.

Here, Michael Williams uses a General Equipment J-1450 electric Jetter to clear a driveway drain with a very stubborn clog.

Keep Your Hose Moving

Another important technique to keep in mind when using jetter hose is to always keep the hose moving. We recommend a back-and-forth motion, two feet in, one foot back and repeat. This motion will accentuate the scouring power of the water jetter and prevent the hose from being caught by grease, sand or other obstructions in the drain. If you let the jetter hose sit in one place too long, the vortex caused by the high-pressure water escaping the nozzles can pack sand and other soft obstructions a foot or so behind the nozzle to the point that you will not be able to remove the hose, even with Vibra-pulse. So always keep that jetter hose moving!

Did you enjoy this post? Be sure to check out parts one, two, four and five!

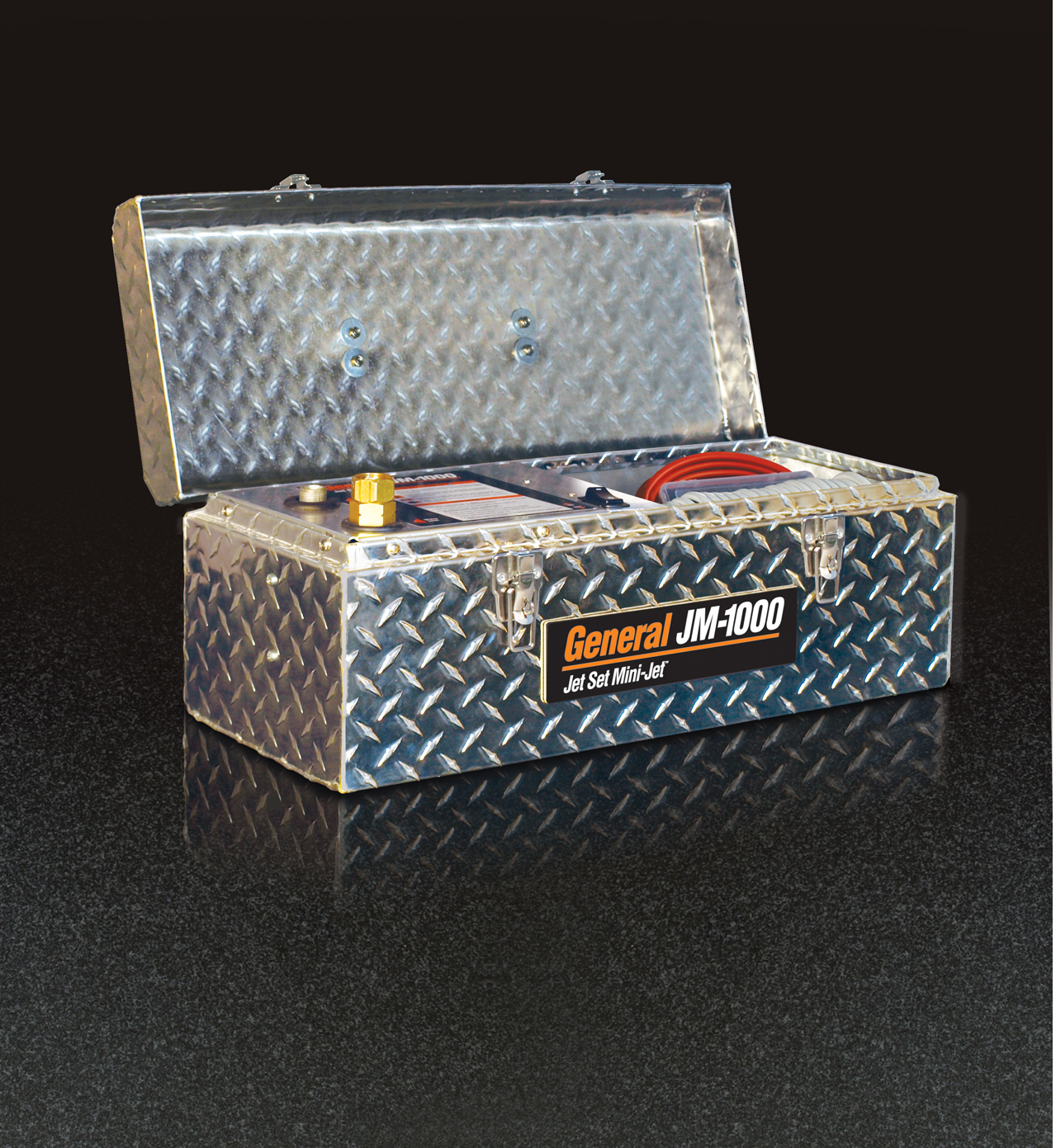

For more information, contact the Drain Brains® at General at 800-245-6200 or by email – [email protected]. You can also communicate with us by using our Contact form too. You can view all of General’s water & sewer jetter systems here, including jetter hoses, jetter nozzles, and jetter accessories such as reels, foot pedals and spray wands. Ready to purchase? Please use our Where to Buy page to find a distributor or retailer near you.