What is Flexible Shaft Technology?

Flexible shaft technology is the next big thing in our industry. Flexible shaft machines utilize a swiftly rotating wire coil, much like a speedometer cable. The flexible shaft is safely protected inside a sheath so it’s easy to handle – no spinning drums.

Flexible shaft technology is faster and more thorough than traditional drain cleaners. The flexible shaft spins more than 10 times faster than drum machines. At speeds of 2000 RPM or more, the chain cutters quickly grind up stoppages and scour the walls of the pipe. And you can use your camera system to give it pinpoint accuracy. General’s new Flexi-Rooter drain cleaner is the next generation in flex-shaft technology.

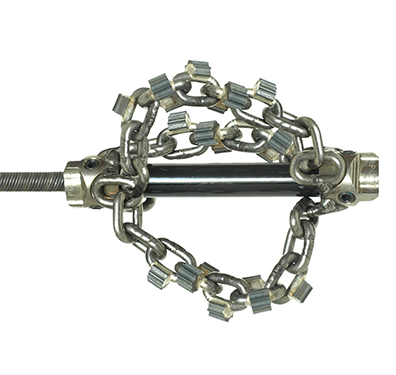

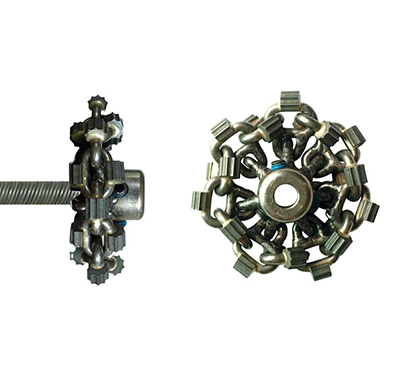

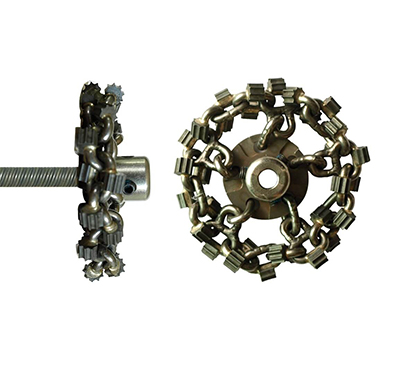

ClogChopper® with Carbide-Tipped Chain Cutter

General’s Innovative, two-part cleaning array combines the unique ClogChopper® with Carbide-Tipped Chain Cutters to make a formidable combination. ClogChoppers rip through tough stoppages with six self-sharpening blades that dig into encrusted debris and root masses, easily grinding up stubborn clogs. The spherical design maneuvers around tight bends and traps. Together, they are capable of boring through tough stoppages and scale, shredding obstructions and scouring pipe walls clean.

General’s stronger, stiffer shaft is flexible enough to get though 2” lines, yet strong enough to cut roots in 4” drain lines up to 75 feet down the line. It’s powered by an integral variable speed motor that lets you adjust the speed from zero to 2200 rpm. With the foot pedal you have both hands free to safely guide the flexible shaft into the line. You can use the Flexi-Rooter simultaneously with your sewer inspection camera system to pinpoint trouble spots in the line and instantly inspect your results.

General’s stronger, stiffer shaft is flexible enough to get though 2” lines, yet strong enough to cut roots in 4” drain lines up to 75 feet down the line. It’s powered by an integral variable speed motor that lets you adjust the speed from zero to 2200 rpm. With the foot pedal you have both hands free to safely guide the flexible shaft into the line. You can use the Flexi-Rooter simultaneously with your sewer inspection camera system to pinpoint trouble spots in the line and instantly inspect your results.